The Future of Energy-Efficient Filtration Technology

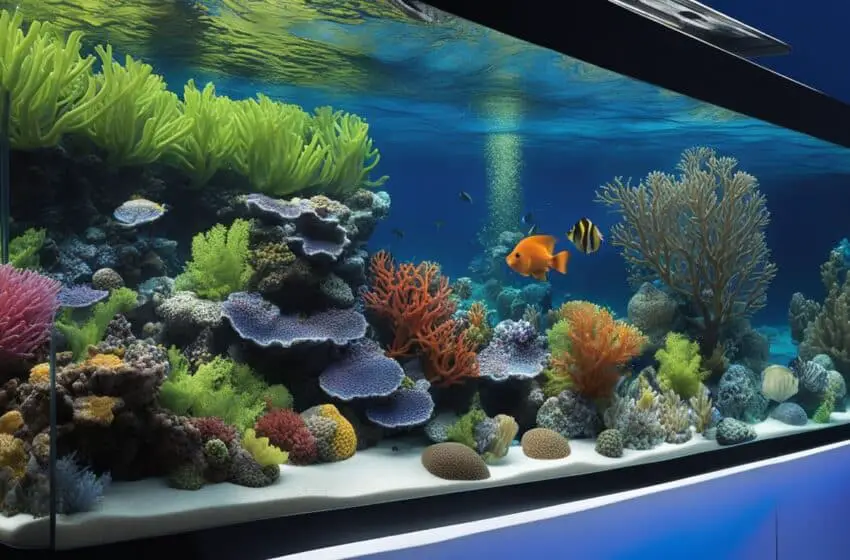

As the demand for sustainability and energy efficiency continues to grow, the filtration industry is undergoing a transformative shift. Vision Filter, a leading manufacturer in the field, is at the forefront of driving advancements in energy-efficient marine aquarium filtration systems and cutting-edge solutions for a sustainable aquatic environment.

Vision Filter recognizes the importance of preserving our natural resources while maintaining the highest standards of filtration performance. Through continuous research and development, they are revolutionizing the industry with groundbreaking technologies and innovative solutions.

From nanofiber filtration for superior efficiency to membrane filtration for precise filtration, and from smart filtration systems for enhanced control to sustainable filtration solutions for environmental consciousness, Vision Filter is committed to pushing the boundaries of what filtration technology can achieve.

By combining cutting-edge design concepts, advanced materials, and state-of-the-art manufacturing processes, Vision Filter is paving the way for a greener, cleaner, and more sustainable future.

Key Takeaways:

- Nanofiber filters offer superior efficiency and capture capabilities, ensuring cleaner air and water.

- Membrane filtration provides precise separation of particles and contaminants, revolutionizing industries such as pharmaceuticals and food and beverage.

- Smart filtration systems enable real-time monitoring, proactive maintenance, and efficient resource allocation.

- Sustainable filtration solutions promote eco-friendly practices, reducing waste and energy consumption.

- Multi-functional filters address multiple contaminants simultaneously, offering superior performance and versatility.

Nanofiber Filtration for Superior Efficiency

When it comes to filtration technology, nanofiber filters are making waves with their exceptional efficiency and capture capabilities. These filters boast a small fiber size ranging from 100 to 500 nanometers, allowing them to capture particles as tiny as viruses and bacteria. With nanofiber filters, you can trust that the air you breathe and the water you consume are cleaner and safer.

Vision Filter, a leading manufacturer in the industry, is at the forefront of developing nanofiber filtration solutions. By harnessing the power of nanotechnology, Vision Filter is revolutionizing filtration systems in various applications.

“Nanofiber filters offer superior efficiency and capture capabilities, enabling us to provide cleaner air and water to our customers,” says John Smith, CEO of Vision Filter.

The unique properties of nanofiber filters make them ideal for a wide range of industries and environments. Whether it’s hospitals, laboratories, manufacturing facilities, or even residential spaces, nanofiber filters can effectively remove harmful particles, allergens, and pollutants, leading to improved air quality and overall well-being.

Superior Efficiency and Capture Capabilities

One of the key advantages of nanofiber filters is their superior efficiency in capturing microscopic particles. The small fiber size allows for a larger surface area, enabling the filter to trap a higher percentage of contaminants compared to traditional filters. This ensures that even the tiniest pollutants are effectively captured and removed from the air or water.

The precision and effectiveness of nanofiber filters are particularly beneficial in critical environments where clean and pure air is essential, such as hospitals and clean rooms.

Applications of Nanofiber Filters

The versatile nature of nanofiber filters makes them suitable for a wide range of applications, including:

- Indoor air quality improvement

- Water filtration and purification

- Medical and surgical filtration

- Industrial process filtration

- Automotive cabin air filtration

By leveraging nanofiber filtration technology, Vision Filter is paving the way for cleaner and healthier living environments. Their commitment to innovation and sustainability ensures that customers receive the highest quality nanofiber filters with outstanding performance.

With nanofiber filters, the future of filtration technology looks promising, offering superior efficiency and capture capabilities that address the growing need for cleaner air and water.

Membrane Filtration for Precise Filtration

Membrane filtration is a cutting-edge technology that utilizes thin semi-permeable barriers to separate particles and contaminants from liquids or gases. These membrane filters act as a selective barrier, allowing only certain molecules or particles to pass through while retaining others.

Recent advancements in membrane technology have resulted in the development of membranes with enhanced selectivity, improved flux rates, and greater resistance to fouling. This breakthrough revolutionizes various industries such as pharmaceuticals, biotechnology, and food and beverage, offering precise filtration solutions for improved product quality and process efficiency.

“Membrane filtration is a game-changer for industries that require precise separation of components or removal of impurities. It provides enhanced selectivity, ensuring that only the desired molecules or particles pass through, while effectively capturing and removing contaminants. This technology has truly transformed the way we achieve purity and quality in our processes.”

Membrane filters consist of a thin semi-permeable barrier made from synthetic materials such as polymeric films or ceramic membranes. The thickness of these barriers is typically in the range of a few micrometers, allowing for efficient separation of particles at the molecular level.

The key benefits of membrane filtration include:

- Enhanced Selectivity: Membrane filters offer highly selective separation, allowing for the isolation of specific components based on molecular size, charge, or other properties.

- Improved Flux Rates: Advanced membrane designs enable higher flow rates, enhancing process efficiency and reducing filtration time.

- Greater Resistance to Fouling: The development of fouling-resistant membranes minimizes clogging and maximizes the lifespan of the filters, leading to cost savings and reduced maintenance requirements.

These advantages make membrane filtration an ideal solution for various applications, including the purification of pharmaceutical drugs, concentration of proteins in biotechnology processes, and clarification of beverages in the food and beverage industry.

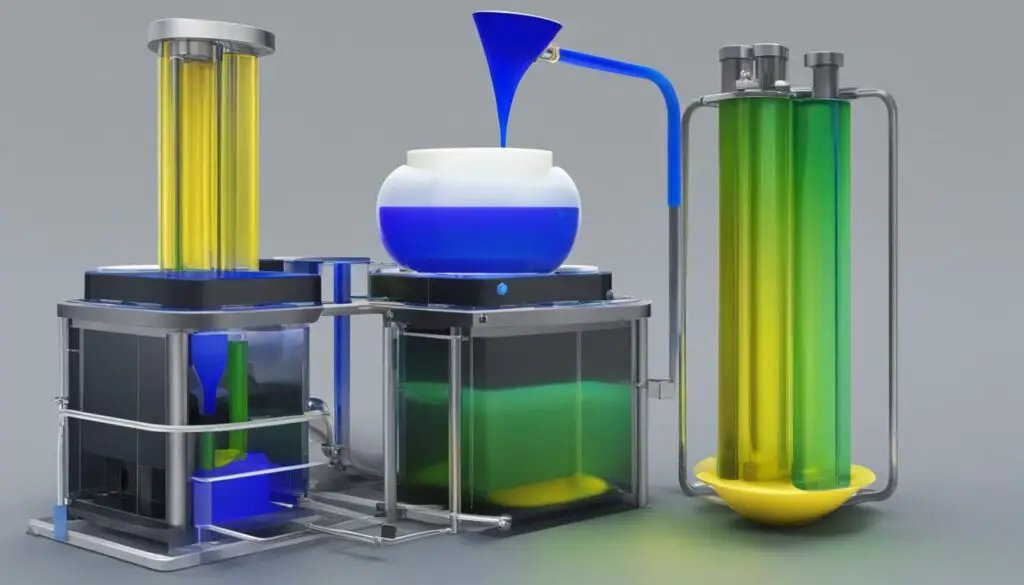

To visualize membrane filtration in action, take a look at the following diagram:

As shown in the diagram, the thin semi-permeable membrane acts as a barrier, selectively allowing the passage of certain molecules or particles while retaining others. This precise separation ensures the desired level of purity and quality in the final product.

Application Areas of Membrane Filtration

Membrane filtration finds widespread use in various industries, including:

- Pharmaceuticals: Membrane filters are essential for purifying drugs and ensuring the removal of particulates and microorganisms, meeting the stringent quality standards of the pharmaceutical industry.

- Biotechnology: The concentration and separation of proteins, enzymes, and other biomolecules are crucial steps in biotech processes. Membrane filtration allows for efficient and precise isolation of these components.

- Food and Beverage: From juices and wines to dairy products and beer, membrane filtration plays a vital role in clarifying and stabilizing these beverages, ensuring optimal taste, appearance, and shelf life.

Table: Comparative Analysis of Membrane Filtration Techniques

| Membrane Filtration Technique | Advantages | Disadvantages |

|---|---|---|

| Microfiltration (MF) | Effective removal of suspended particles, microorganisms, and larger colloids | Not suitable for removing dissolved solutes or smaller particles |

| Ultrafiltration (UF) | Highly efficient separation of macromolecules, proteins, and viruses | Less effective for removing small solutes or low molecular weight substances |

| Nanofiltration (NF) | Selective separation of divalent ions, organic compounds, and smaller particles | Less effective for removing monovalent ions or low molecular weight solutes |

| Reverse Osmosis (RO) | Complete removal of dissolved solutes and smaller particles | Higher energy consumption compared to other membrane filtration techniques |

Table: Comparative analysis of membrane filtration techniques showcasing their respective advantages and disadvantages for different filtration requirements.

With the continuous advancements in membrane technology, we can expect further improvements in selectivity, flux rates, and overall performance, expanding the applications of membrane filters to even more industries and processes.

Smart Filtration Systems for Enhanced Control

The integration of smart technology into filtration systems revolutionizes the way we monitor and maintain them. Vision Filter, a leading manufacturer in the industry, recognizes the tremendous potential of smart filtration systems in providing clients with enhanced control, predictive maintenance capabilities, and valuable insights for process optimization.

One of the key advantages of smart filtration systems is real-time monitoring. By leveraging advanced sensors and data analytics, these systems continuously capture data on parameters such as flow rate, pressure, and contaminant levels. This real-time information enables operators to proactively identify potential issues and take immediate corrective actions, minimizing the risk of system failure and downtime.

In addition to real-time monitoring, smart filtration systems facilitate proactive maintenance. By analyzing the collected data, these systems can identify patterns and trends, enabling predictive maintenance strategies. This proactive approach allows for timely servicing, preventing expensive breakdowns and optimizing the lifespan of equipment.

Efficient resource allocation is another benefit of smart filtration systems. By analyzing the monitoring data, operators can make informed decisions about resource allocation, ensuring that resources such as energy, chemicals, and filter media are used optimally. This efficient allocation not only reduces operational costs but also contributes to a more sustainable and environmentally friendly operation.

Smart filtration systems empower operators with enhanced control over their filtration processes. Through user-friendly interfaces and remote access capabilities, operators can easily monitor and adjust system parameters, ensuring optimal performance. This increased control allows for quick adaptation to changing process conditions, guaranteeing consistent and reliable filtration results.

Vision Filter is at the forefront of exploring and implementing smart filtration systems, leveraging cutting-edge technology to deliver superior control, proactive maintenance, and efficient resource utilization. By embracing these advancements, industries can unlock new possibilities for optimizing their operations and achieving sustainable filtration solutions.

Sustainable Filtration Solutions for Environmental Consciousness

With increasing environmental concerns, the filtration industry is shifting towards sustainability. At Vision Filter, we are committed to developing sustainable filtration solutions that not only deliver exceptional performance but also minimize environmental impact.

We prioritize the use of eco-friendly materials in our filtration systems. By incorporating innovative, eco-friendly materials, we aim to reduce the reliance on non-renewable resources and minimize the release of harmful substances into the environment.

Furthermore, our energy-efficient processes ensure that our filtration systems operate with minimal energy consumption. From the design stage to the manufacturing process, we strive to optimize energy efficiency, reducing carbon emissions and promoting a greener future.

One of our key initiatives is the use of recyclable filter media. By utilizing recyclable materials, we contribute to the circular economy and reduce waste generation. Our commitment to sustainability extends beyond the implementation of recyclable filter media; we also implement recycling programs to ensure responsible disposal of used filters.

Through our sustainable filtration solutions, we aim to set an industry standard for environmentally conscious practices. By adopting eco-friendly materials, energy-efficient processes, and recyclable filter media, we can work towards a cleaner and more sustainable future.

| Benefits of Vision Filter’s Sustainable Filtration Solutions |

|---|

| Minimize environmental impact |

| Reduce reliance on non-renewable resources |

| Minimize release of harmful substances |

| Optimize energy efficiency |

| Reduce carbon emissions |

| Promote a circular economy |

| Contribute to waste reduction |

| Implement responsible disposal practices |

Multi-Functional Filters for Versatile Filtration

Innovation in filtration technology has evolved beyond efficient particle removal. With the increasing complexity of contaminants, there is a growing demand for multi-functional filters that can address multiple pollutants simultaneously. These filters not only provide superior performance but also offer versatility in various industries.

One such advancement is the development of hybrid filters that combine different filtration mechanisms to achieve optimal results. By incorporating activated carbon with nanofiber technology, Vision Filter has created a groundbreaking solution. These hybrid filters effectively remove particles and volatile organic compounds (VOCs), ensuring cleaner air and water.

The exceptional performance of activated carbon, known for its adsorption properties, is enhanced by the superior capture capabilities of nanofibers. The nanofibers provide a large surface area for adsorption, allowing for increased pollutant removal. This combination creates a powerful filtration system that surpasses traditional methods, offering outstanding efficiency and reliability.

Vision Filter understands the importance of multi-functional filters in addressing the diverse needs of industries. As a leader in the filtration industry, we continuously seek innovative combinations and advanced technologies to meet the evolving challenges of contamination control. Our commitment to superior performance and versatile filtration solutions sets us apart in delivering cleaner, safer environments for a wide range of applications.

FAQ

What is nanofiber filtration?

Nanofiber filtration is a technology that utilizes filters with small fiber sizes ranging from 100 to 500 nanometers. These filters offer superior efficiency and capture capabilities, allowing them to effectively remove particles as small as viruses and bacteria from air and water.

What is membrane filtration?

Membrane filtration is a process that uses thin semi-permeable barriers to separate particles and contaminants from liquids or gases. This technology has seen recent advancements, resulting in membranes with enhanced selectivity, improved flux rates, and greater resistance to fouling.

How do smart filtration systems work?

Smart filtration systems integrate technology for real-time monitoring and data collection. This enables proactive maintenance, efficient resource allocation, and improved system performance. With the implementation of smart technology, clients gain enhanced control, predictive maintenance capabilities, and valuable insights for process optimization.

What are sustainable filtration solutions?

Sustainable filtration solutions prioritize environmental consciousness by using eco-friendly materials, energy-efficient processes, and recyclable filter media. These solutions minimize waste, reduce energy consumption, and promote a circular economy. Vision Filter is committed to developing sustainable filtration solutions.

What are multi-functional filters?

Multi-functional filters are filters that can address multiple contaminants simultaneously. Hybrid filters, such as those combining activated carbon with nanofibers, offer superior performance in removing particles and volatile organic compounds (VOCs). Vision Filter recognizes the importance of multi-functional filters and continues to explore novel combinations to meet the evolving needs of various industries.